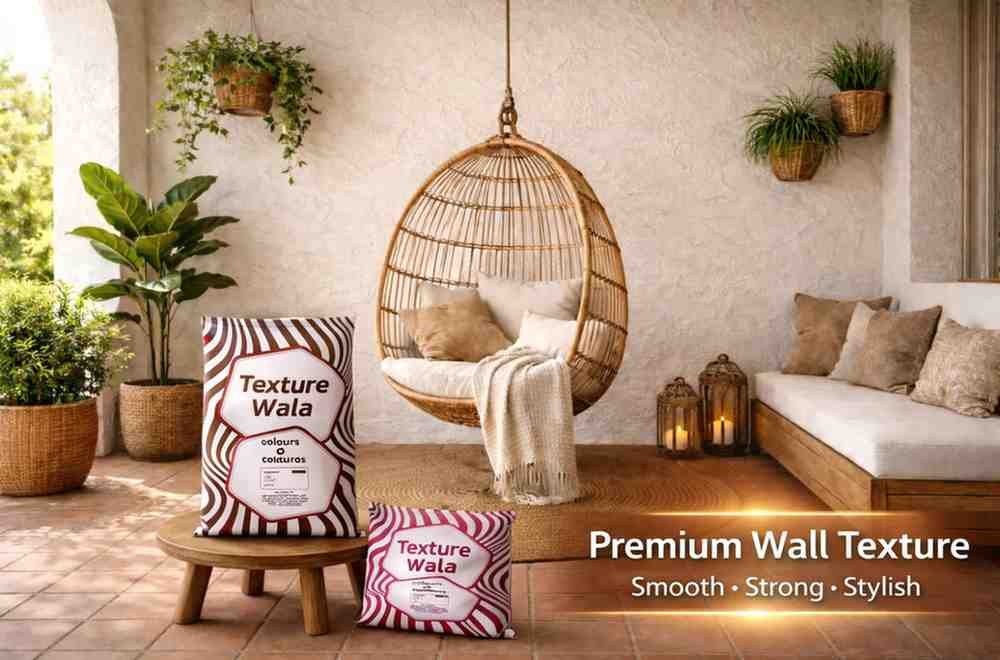

When it comes to enhancing walls with durability and decorative appeal, choosing the right Texture manufacturer in Sadak Arjuni becomes extremely important. Textured finishes are no longer limited to luxury homes — they are now widely used in residential, commercial, and institutional projects across the region.

A reliable local texture manufacturer ensures consistent supply, climate-suitable formulations, and better coordination with builders. In this detailed guide, we will explore everything about selecting and working with a texture manufacturer in Sadak Arjuni.

📌 Index

- Introduction to Texture Manufacturing

- Growing Demand for Wall Textures in Sadak Arjuni

- What Does a Texture Manufacturer Do?

- Types of Wall Textures Available

- Interior Texture Solutions

- Exterior Texture Solutions

- Raw Materials Used in Texture Production

- Manufacturing Process Overview

- Quality Control Standards

- Benefits of Choosing a Local Texture Manufacturer

- Cost Advantages for Builders

- Applications Across Residential Projects

- Commercial & Industrial Use Cases

- Supply Chain & Delivery Efficiency

- Customization & Shade Consistency

- Common Challenges in Texture Projects

- Storage & Handling Guidelines

- How to Choose the Right Texture Manufacturer in Sadak Arjuni

- Future Trends in Wall Textures

- Conclusion

1. Introduction to Texture Manufacturing

A Texture manufacturer in Sadak Arjuni produces decorative and protective wall texture materials suitable for local construction requirements. These products are designed to improve wall strength, surface appeal, and resistance against environmental conditions.

Unlike plain paint, textures provide depth, patterns, and enhanced durability. Local manufacturing ensures better alignment with regional climate and project timelines.

2. Growing Demand for Wall Textures in Sadak Arjuni

Construction activities in Sadak Arjuni have increased steadily in recent years. With modern housing preferences and commercial development, textured finishes are becoming a popular choice.

Reasons for Rising Demand:

- Decorative elevation finishes

- Crack coverage solutions

- Premium appearance for homes

- Long-term surface durability

Builders prefer textured walls because they combine functionality with aesthetics.

3. What Does a Texture Manufacturer Do?

A texture manufacturer handles multiple responsibilities beyond simple production.

| Function | Description |

|---|---|

| Formulation Development | Designing texture mixes suitable for interior and exterior use |

| Raw Material Sourcing | Procuring cement, polymers, additives, and pigments |

| Production & Mixing | Batch-wise controlled manufacturing |

| Quality Testing | Ensuring consistency and performance |

| Packaging & Distribution | Bulk supply for builders and contractors |

A professional texture manufacturer in Sadak Arjuni maintains uniform standards across all batches.

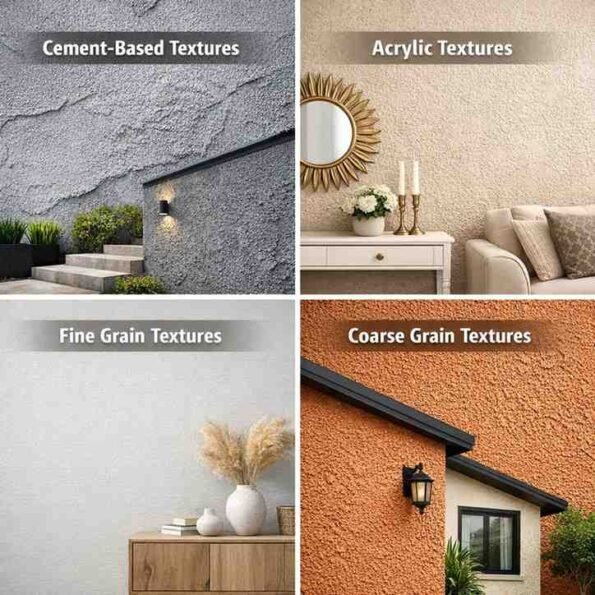

4. Types of Wall Textures Available

Different projects require different types of textures. Local manufacturers usually offer:

1. Cement-Based Textures

Durable and suitable for exterior walls. Ideal for high-exposure areas.

2. Acrylic Textures

Flexible and crack-resistant. Commonly used for decorative interiors.

3. Fine Grain Textures

Smooth and elegant finish. Perfect for modern homes.

4. Coarse Grain Textures

Bold patterns for elevations and compound walls.

5. Interior Texture Solutions

Interior walls demand smoother and decorative finishes.

Common Interior Applications:

- Living room feature walls

- Bedroom accent walls

- Hotel lobbies

- Office cabins

Interior textures provide elegance while hiding minor surface imperfections.

6. Exterior Texture Solutions

Exterior walls are constantly exposed to harsh environmental conditions such as heat, dust, rain, humidity, and UV radiation. Because of this, selecting the right product from a reliable Texture manufacturer in Sadak Arjuni becomes essential for long-term durability and appearance.

Exterior textures are not just decorative finishes — they act as a protective shield for the building structure.

Why Exterior Walls Need Specialized Textures

Unlike interior surfaces, exterior walls face continuous temperature fluctuations and moisture exposure. A professional Texture manufacturer in Sadak Arjuni formulates products specifically designed to handle these regional climate challenges.

Exterior texture systems are developed to provide strength, flexibility, and lasting color stability.

Key Exterior Benefits

1. UV Resistance

Strong sunlight can cause fading and surface breakdown. Exterior textures designed with UV-resistant components help maintain color vibrancy and prevent early deterioration.

Example:

Homes facing direct west sunlight maintain their original shade for years without visible fading.

2. Crack Resistance

Buildings expand and contract due to temperature changes. Flexible texture formulations reduce the risk of visible cracks on external walls.

Example:

During seasonal temperature shifts, the textured surface adjusts slightly without forming hairline cracks.

3. Weather Durability

Rain, wind, and dust exposure can weaken ordinary coatings. Exterior textures from a trusted Texture manufacturer in Sadak Arjuni are built to withstand such environmental stress.

Example:

Even after heavy monsoon exposure, the surface remains intact without peeling or blistering.

4. Long Color Retention

High-quality pigments and binders ensure that exterior walls maintain their appearance for extended periods.

Example:

Commercial buildings retain a fresh and uniform look, reducing the need for frequent repainting.

Additional Advantages of Exterior Texture Solutions

- Improved surface strength

- Better resistance against minor surface damage

- Reduced maintenance frequency

- Enhanced architectural appearance

Exterior textures protect as well as beautify the structure, offering both functional and aesthetic value.

Choosing the right Texture manufacturer in Sadak Arjuni for exterior applications ensures durability, long-term savings, and consistent performance. Properly formulated exterior textures not only enhance building elevation but also extend the lifespan of wall surfaces.

7. Raw Materials Used in Texture Production

High-quality raw materials determine the final performance of the product.

| Raw Material | Purpose |

|---|---|

| White Cement | Base binding material |

| Polymers | Flexibility and adhesion |

| Graded Sand | Texture pattern formation |

| Additives | Workability and drying control |

| Pigments | Color consistency |

Proper material selection ensures uniform finish across projects.

8. Manufacturing Process Overview

A structured process ensures consistent product quality.

Steps Involved:

- Raw material inspection

- Controlled batch mixing

- Moisture level monitoring

- Sample testing

- Packaging in moisture-resistant bags

Every batch undergoes testing before dispatch.

9. Quality Control Standards

Quality is one of the most important factors when selecting a Texture manufacturer in Sadak Arjuni. Texture materials must deliver consistent performance across multiple projects, surfaces, and environmental conditions. Even minor variations in formulation can affect durability, adhesion, and final appearance.

A professional Texture manufacturer in Sadak Arjuni follows structured quality control processes to ensure every batch meets defined performance standards before reaching the project site.

Quality is not checked at the end — it is monitored at every stage of production.

Why Quality Control Matters

Texture finishes are thicker and more performance-based than standard paints. If quality standards are weak, problems such as peeling, uneven patterns, or shade differences may appear after application. Strong testing procedures prevent such site-level complications.

Consistent quality today prevents repair costs tomorrow.

Key Testing Parameters

1. Adhesion Strength

Adhesion determines how well the texture bonds to the wall surface. Poor bonding can lead to peeling or flaking over time.

A reliable Texture manufacturer in Sadak Arjuni conducts adhesion testing to ensure:

- Strong surface grip

- Long-term bonding performance

- Resistance against surface separation

Strong adhesion forms the foundation of a durable textured wall.

2. Workability

Workability refers to how easily the texture material can be applied on walls. The right consistency ensures smooth spreading and proper pattern formation.

Manufacturers test for:

- Proper mixing behavior

- Smooth application flow

- Consistent grain distribution

Good workability ensures faster application and uniform finish.

3. Drying Time

Controlled drying time is essential for both efficiency and durability. If drying is too fast, cracks may appear. If too slow, project timelines may suffer.

A professional Texture manufacturer in Sadak Arjuni evaluates drying performance to ensure:

- Balanced curing process

- Stable surface formation

- Reduced risk of moisture damage

Balanced drying creates stronger and more stable surfaces.

4. Surface Crack Resistance

Exterior walls face temperature variations and structural movement. Texture materials must resist minor expansion and contraction without cracking.

Testing ensures:

- Flexibility under stress

- Durability in changing climates

- Long-term structural protection

Crack resistance preserves both beauty and strength.

5. Shade Consistency

Uniform shade is essential, especially for large projects. Even slight variation between batches can impact the final visual appearance.

Quality control measures ensure:

- Stable pigment distribution

- Batch-to-batch uniformity

- Consistent color tone across surfaces

Uniform shade reflects professional manufacturing standards.

Importance of Batch Uniformity

Uniformity across batches reduces site-level issues such as patchy walls, visible shade differences, and rework expenses. When a dependable Texture manufacturer in Sadak Arjuni maintains strict quality checks, contractors can confidently execute large projects without worrying about inconsistencies.

Consistency builds trust. Trust builds long-term partnerships.

Final Thought

Quality control is not just a technical process — it is a commitment to performance, durability, and customer satisfaction. Choosing a reliable Texture manufacturer in Sadak Arjuni ensures that every texture application delivers strength, beauty, and long-lasting results.

10. Benefits of Choosing a Local Texture Manufacturer

Working with a local manufacturer provides multiple advantages:

1. Faster Delivery

Shorter transportation routes reduce waiting time.

2. Better Communication

Direct coordination improves efficiency.

3. Quick Issue Resolution

On-site support becomes easier.

4. Reliable Stock Availability

Continuous supply avoids project delays.

11. Cost Advantages for Builders

Bulk sourcing from a texture manufacturer in Sadak Arjuni helps control project budgets.

| Cost Factor | Impact |

|---|---|

| Reduced Transport | Lower logistics cost |

| Bulk Purchase | Lower per-unit rate |

| Stable Pricing | Budget predictability |

| Minimal Delays | Reduced labor idle cost |

Cost transparency improves financial planning.

12. Applications Across Residential Projects

Residential construction contributes significantly to the overall demand for textured finishes. Homeowners today are not only focused on durability but also on aesthetics and long-term value. This has increased the use of wall textures in various types of housing projects.

A reliable Texture manufacturer in Sadak Arjuni plays an important role in supporting residential construction by providing consistent materials suitable for different home styles and surface conditions.

Textured finishes in residential projects are chosen for their ability to enhance appearance while offering surface protection.

Why Residential Projects Prefer Textures

Modern homeowners want walls that are visually appealing, easy to maintain, and long-lasting. Textures offer:

- Decorative patterns and depth

- Crack coverage for minor imperfections

- Better durability compared to plain finishes

- Enhanced elevation appearance

Textures are now widely used both inside homes and on exterior elevations.

Common Uses in Residential Projects

1. Independent Houses

Individual homes often use textures to create attractive exterior elevations or feature interior walls. Textured finishes help enhance the architectural design of the house.

For independent houses, textures provide:

- Premium exterior appearance

- Weather protection

- Long-lasting finish

- Reduced repainting frequency

This makes them ideal for homeowners looking for both beauty and durability.

2. Apartment Buildings

In apartment complexes, uniform appearance across multiple units is important. Textures help maintain consistency in exterior finishing and common areas.

Apartment projects benefit from:

- Uniform surface finish

- Improved durability in shared spaces

- Enhanced building elevation design

- Long-term maintenance savings

Large residential projects often rely on a trusted Texture manufacturer in Sadak Arjuni to maintain batch consistency across multiple blocks.

3. Housing Societies

Housing societies frequently choose textures for boundary walls, clubhouses, and building exteriors. Textured surfaces provide strength and resist wear caused by weather exposure and daily use.

Advantages for housing societies include:

- Stronger wall protection

- Reduced surface damage

- Attractive common area appearance

- Lower long-term maintenance cost

Textures add a modern look while maintaining structural protection.

4. Renovation Projects

Residential renovation and repainting projects also utilize textures to upgrade the overall look of older buildings. Textures help cover minor surface cracks and uneven patches that develop over time.

During renovation, textures offer:

- Improved wall finish without major structural changes

- Modernized exterior design

- Better surface coverage

- Enhanced property value

This makes textured finishes a practical solution for property upgrades.

Long-Term Value for Homeowners

Across all residential segments — from independent houses to large housing societies — textures contribute to durability, visual appeal, and cost efficiency. When sourced from a dependable Texture manufacturer in Sadak Arjuni, these finishes ensure uniformity, strong adhesion, and consistent performance.

Residential projects continue to drive texture demand because they combine decorative impact with protective functionality, making them a smart choice for modern homes.asonable cost.

13. Commercial & Industrial Use Cases

Commercial projects require durable and visually appealing surfaces.

Applications Include:

- Retail showrooms

- Educational institutions

- Office complexes

- Warehouses

Textures enhance durability in high-traffic areas.

14. Supply Chain & Delivery Efficiency

Efficient logistics play a key role in large projects.

Advantages of Local Supply:

- Shorter delivery routes

- Easier inventory planning

- Faster replenishment

This ensures uninterrupted workflow.

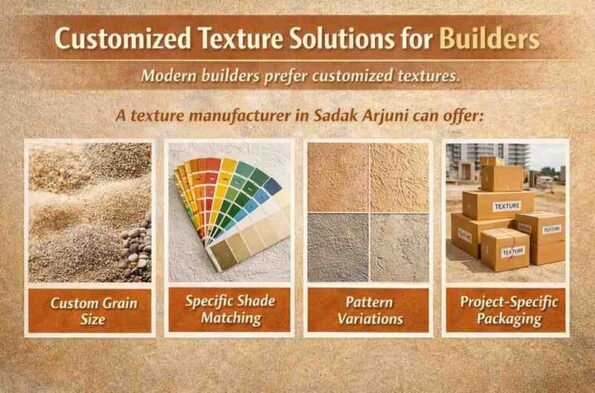

15. Customization & Shade Consistency

Modern builders prefer customized textures.

A texture manufacturer in Sadak Arjuni can offer:

- Custom grain size

- Specific shade matching

- Pattern variations

- Project-specific packaging

Batch consistency ensures uniform wall appearance.

16. Common Challenges in Texture Projects

Even when high-quality materials are used, texture application requires proper planning, surface preparation, and execution. Textured finishes are thicker and more pattern-oriented than regular paint, which means small mistakes can become visible on large surfaces.

Understanding common challenges helps builders and contractors prevent delays, rework, and additional costs.

Why Texture Projects Need Careful Execution

Texture materials behave differently from standard wall paints. They require correct base preparation, controlled mixing, and skilled application techniques. Without proper coordination, the final finish may not achieve the expected durability or appearance.

Possible Issues in Texture Projects

1. Incorrect Surface Preparation

Surface preparation is the foundation of a successful texture finish. If the wall is not properly cleaned, leveled, or primed, adhesion problems may occur. Dust, loose particles, oil stains, or old flaky paint can reduce bonding strength, leading to peeling or cracking over time.

Proper surface inspection and priming are essential before applying any texture material.

2. Improper Mixing Ratios

Texture materials often require specific water-to-material ratios. Adding too much water can weaken the mix and affect durability, while insufficient water may make the material difficult to spread.

Maintaining correct mixing proportions ensures:

- Smooth application

- Consistent pattern formation

- Better adhesion strength

Following manufacturer-recommended mixing guidelines prevents avoidable defects.

3. Uneven Application

Texture finishes are decorative in nature. Uneven application can result in inconsistent patterns, visible patch lines, or thickness variations.

This may happen due to:

- Inexperienced labor

- Incorrect tools

- Rushed execution

Proper supervision and skilled applicators help maintain uniform texture across large surfaces.

4. Moisture Exposure Before Drying

Moisture is one of the biggest risks in texture projects. If walls are exposed to rain, high humidity, or water leakage before the texture fully cures, surface damage may occur.

Premature moisture exposure can cause:

- Bubbling

- Surface softening

- Reduced durability

Allowing adequate drying time and monitoring weather conditions is crucial, especially for exterior projects.

How Choosing the Right Manufacturer Helps

A reliable manufacturer reduces project risks by offering:

- Consistent product formulation

- Clear usage instructions

- Batch uniformity

- Stable material quality

While application practices remain important, high-quality materials significantly lower the chances of failure.

17. Storage & Handling Guidelines

Proper storage ensures product performance.

| Guideline | Purpose |

|---|---|

| Keep in dry area | Prevent moisture damage |

| Store above ground | Avoid dampness |

| Use within recommended time | Maintain workability |

| Seal opened bags properly | Avoid contamination |

18. How to Choose the Right Texture Manufacturer in Sadak Arjuni

Selecting the right supplier is a critical decision for builders, contractors, and property owners. The performance, durability, and finish quality of textured walls depend heavily on the manufacturer’s production standards and supply reliability.

Before finalizing a supplier, it is important to evaluate several key factors to ensure you are working with a dependable Texture Manufacturer in Sadak Arjuni.

1. Production Capacity

A reliable Texture Manufacturer in Sadak Arjuni should have sufficient production capacity to handle both small and large-scale projects. Limited production capability can lead to supply shortages, especially during peak construction seasons.

Adequate manufacturing capacity ensures:

- Continuous material availability

- Timely delivery for bulk projects

- Reduced risk of project delays

For large residential or commercial developments, steady supply is essential.

2. Batch Consistency

Texture finishes require uniformity across walls and surfaces. Even slight variation between batches can affect the overall appearance of a project.

A professional Texture Manufacturer in Sadak Arjuni maintains strict batch control to ensure:

- Consistent grain size

- Uniform shade tone

- Stable material thickness

- Predictable application performance

Batch consistency directly impacts visual appeal and long-term durability.

3. Delivery Capability

Timely delivery plays a major role in project management. Delays in texture material supply can slow down construction timelines and increase labor costs.

Choose a Texture Manufacturer in Sadak Arjuni with:

- Efficient logistics system

- Shorter delivery routes

- Quick replenishment capability

Reliable delivery ensures uninterrupted workflow at the project site.

4. Price Transparency

Clear pricing structure helps builders manage budgets effectively. Hidden costs or sudden price changes can disrupt financial planning.

A trustworthy Texture Manufacturer in Sadak Arjuni provides:

- Clear quotations

- Stable pricing agreements

- Transparent billing

This allows contractors to calculate project costs accurately and maintain profit margins.

5. Market Reputation

Reputation reflects reliability and product performance. Checking feedback from builders, contractors, and retailers can provide valuable insights.

An established Texture Manufacturer in Sadak Arjuni usually demonstrates:

- Consistent product quality

- Professional communication

- Long-term client relationships

- Positive project outcomes

Market reputation is often built through years of dependable service.

Choosing the right Texture Manufacturer in Sadak Arjuni is not just about price — it is about reliability, consistency, and long-term value. Evaluating production capacity, batch consistency, delivery strength, pricing transparency, and reputation ensures better project outcomes.

A reliable texture manufacturer ensures long-term project success by supporting quality construction, timely execution, and durable finishes.

19. Future Trends in Wall Textures

The demand for innovative finishes is increasing.

Emerging Trends:

- Minimalist smooth textures

- Earth-tone finishes

- Eco-friendly formulations

- Low-maintenance coatings

Builders are shifting toward durable yet decorative solutions.

20. Conclusion

Selecting the right Texture manufacturer in Sadak Arjuni directly impacts project quality, cost efficiency, and delivery timelines. Local manufacturers provide better coordination, faster supply, and consistent product standards.

Whether for residential homes or commercial buildings, textured finishes offer durability and aesthetic value. Partnering with a trusted local manufacturer ensures smooth execution and long-lasting results.