A reliable paint manufacturer in Salekasa can make a big difference in project quality, timelines, and overall cost control. Whether you are managing a residential construction site, a commercial repainting contract, or a retail supply chain, sourcing from a manufacturer (instead of depending only on distant distributors) improves consistency, reduces delays, and supports smoother execution.

In this guide, you’ll learn how a paint manufacturer in Salekasa typically operates, what product categories to expect, how quality is maintained, how to evaluate rates and batch consistency, and what practical questions to ask before finalizing your supplier.

Index

- Introduction: Why Local Manufacturing Matters

- What a Paint Manufacturer in Salekasa Does

- Who Benefits Most (Builders, Contractors, Retailers, Institutions)

- Product Categories Commonly Manufactured

- Interior Paints: Options, Finishes, and Best Uses

- Exterior Paints: Weather Protection and Durability

- Primers, Putty, and Surface Preparation Materials

- Decorative & Specialty Coatings (Optional Add-ons)

- Raw Materials & Formulation Basics (Simple, Practical View)

- Quality Control: Key Checkpoints That Matter

- Shade Consistency & Batch Reliability for Large Projects

- Packaging Standards & Transport Safety

- Bulk Orders: Pricing Logic and Cost Control

- Delivery Planning, Stock Availability, and Lead Time

- Storage & Handling on Site (Avoid Spoilage and Waste)

- How to Choose the Right Paint Manufacturer in Salekasa

- Common Mistakes Buyers Make (and How to Avoid Them)

- Simple Selection Checklist + Comparison Tables

- FAQs (Buyer Questions People Usually Ask)

- Conclusion

1. Introduction: Why Local Manufacturing Matters

A paint manufacturer in Salekasa is not just a seller—it’s a production source. That means better control over supply cycles, more predictable batches, and improved coordination when your project needs repeat orders in the same shade and finish.

For builders and contractors, paint is not a “last-minute purchase.” It is a finishing material that directly affects site handover, client satisfaction, and maintenance complaints. A dependable local manufacturer helps reduce three major site risks:

- Stock-outs during finishing stage

- Shade variation across rooms or elevations

- Unplanned cost spikes due to urgent procurement

2. What a Paint Manufacturer in Salekasa Does

A professional paint manufacturer in Salekasa typically handles:

- Procurement and testing of raw materials

- Batch-wise production (mixing, dispersion, tinting)

- Viscosity and shade control checks

- Packaging in buckets/containers with proper sealing

- Dispatch planning for retailers and bulk buyers

Because manufacturing happens closer to demand, the response time for replenishment can be faster—especially helpful when sites expand scope or add extra coating cycles.

3. Who Benefits Most

A paint manufacturer in Salekasa can serve multiple buyer types:

- Builders & Contractors: Bulk supply, consistent batches, predictable scheduling

- Retailers/Dealers: Regular inventory flow, common shades, faster replenishment

- Institutions (Schools, Offices, Hospitals): Large-area painting, safer low-odor options

- Homeowners (Direct Purchase): Budget-friendly packs, local shade preferences

The biggest value shows up where repeat supply is required: apartment blocks, multi-phase projects, or contracts with strict deadlines.

4. Product Categories Commonly Manufactured

Most local manufacturers cover a practical range. Here’s a simple view:

| Category | Typical Use | Why It Matters |

|---|---|---|

| Interior Wall Paints | Bedrooms, living rooms, ceilings | Ensures smooth finish quality and low odor performance |

| Exterior Wall Paints | Facades, boundary walls | Provides strong weather resistance and durability |

| Primers | New walls, repaint base | Improves adhesion and ensures uniform absorption |

| Waterproof / Protective Coatings | Damp-prone zones | Prevents seepage marks and moisture-related damage |

A good paint manufacturer in Salekasa will also guide (at least at a basic level) which product system works best for the wall condition and budget.

5. Interior Paints: Options, Finishes, and Best Uses

Interior painting is where customers notice imperfections the most—patchiness, roller marks, uneven sheen, or shade mismatch. That’s why interior products need consistent spread and smooth film formation.

Common interior options you may find from a paint manufacturer in Salekasa include:

- Matt finish: Hides minor surface defects; good for ceilings and low-traffic rooms

- Silk / soft sheen: Easier cleaning; premium look for living areas

- Washable options: Better stain resistance; useful for kids’ rooms, corridors

What to check before buying interior paint in bulk

- Coverage per coat (practical expectation, not only brochure claims)

- Workability (roller flow, leveling, open time)

- Drying time (fast enough for site planning, not so fast that it drags)

- Smell/odor level (important for occupied repainting)

6. Exterior Paints: Weather Protection and Durability

Exterior walls face sunlight, rain, dust, and temperature swings. A reliable paint manufacturer in Salekasa should offer exterior options designed to:

- Reduce chalking and fading

- Improve water resistance

- Reduce fungal/algae growth (where applicable)

- Maintain surface strength against dust and pollution

Exterior system tip (simple and practical)

For best outcomes on fresh plaster, the typical approach is: primer + putty (if needed) + 2 coats exterior paint. The exact products vary, but the “system approach” matters more than chasing one fancy bucket.

7. Primers, Putty, and Surface Preparation Materials

Many paint failures happen due to weak base preparation, not because the topcoat is bad. A good paint manufacturer in Salekasa usually provides primers and wall care products that improve:

- Adhesion (paint sticks properly)

- Uniform absorption (prevents patchy shade)

- Surface smoothness (premium finish becomes possible)

Practical base issues primers help with

- New plaster with high suction

- Mild powdering (after proper cleaning)

- Repaint surfaces with uneven porosity

8. Decorative & Specialty Coatings

Some manufacturers also supply specialty products like:

- Textured finishes (limited range)

- Damp-proof coatings

- Heat-reflective coatings

- Wood/metal protective enamels

If your project scope includes premium interiors or feature walls, ask the paint manufacturer in Salekasa whether they can maintain consistency on decorative finishes—because these are more sensitive to mixing variation.

9. Raw Materials & Formulation Basics

You don’t need to be a chemist—but knowing the basics helps you compare quality logically.

Typical paint formulation includes:

- Binders/resins: Film strength, adhesion, durability

- Pigments: Shade, hiding power

- Fillers/extenders: Smoothness, cost balance, texture

- Solvents/water: Viscosity control and application ease

- Additives: Anti-foam, anti-fungal, flow/leveling

A responsible paint manufacturer in Salekasa focuses on consistency of these inputs so batches remain stable across months.

10. Quality Control: Key Checkpoints That Matter

Quality control isn’t just a lab term—it impacts site results.

Here are practical checkpoints you should expect:

| Checkpoint | What it Controls | Site Impact |

|---|---|---|

| Raw material inspection | Input consistency | Reduces sudden performance shifts |

| Shade matching & tint control | Color accuracy | Prevents shade complaints |

| Viscosity consistency | Flow, leveling | Avoids roller marks & patchiness |

| Coverage/hiding check | Opacity | Fewer coats = cost savings |

| Drying & adhesion tests | Film reliability | Reduces peeling/flaking risks |

| Batch labeling | Traceability | Easier repeat orders |

If a paint manufacturer in Salekasa can show batch codes and maintain repeatability, it’s a strong sign of organized production.

11. Shade Consistency & Batch Reliability for Large Projects

For apartments and big sites, shade consistency is a non-negotiable requirement.

When you reorder after 2–3 weeks, you want the same shade to match existing walls. To reduce risk:

- Order major quantities in planned phases (avoid tiny emergency orders)

- Keep a small retained sample for comparison

- Ask for batch coding and consistent tinting method

A dependable paint manufacturer in Salekasa will support repeatability through controlled mixing and standardized tint procedures.

12. Packaging Standards & Transport Safety

Packaging quality affects wastage. Poor lids, weak buckets, or improper sealing leads to:

- Leakage during transport

- Skin formation inside container

- Contamination due to dust/water entry

Before choosing a paint manufacturer in Salekasa, check:

- Bucket strength and lid locking quality

- Inner sealing (where applicable)

- Proper labeling: shade, batch, manufacturing date

13. Bulk Orders: Pricing Logic and Cost Control

Bulk ordering is not just “cheaper.” It also improves planning.

Cost advantages of buying from a paint manufacturer in Salekasa:

- Lower per-unit cost due to higher quantity

- Reduced transport and handling overhead

- Stable rates across project duration (when agreed early)

- Better budgeting accuracy and fewer purchase surprises

Smart approach

Ask for a rate structure by quantity slab (example: 50 buckets, 100 buckets, 200 buckets). This makes your procurement predictable.

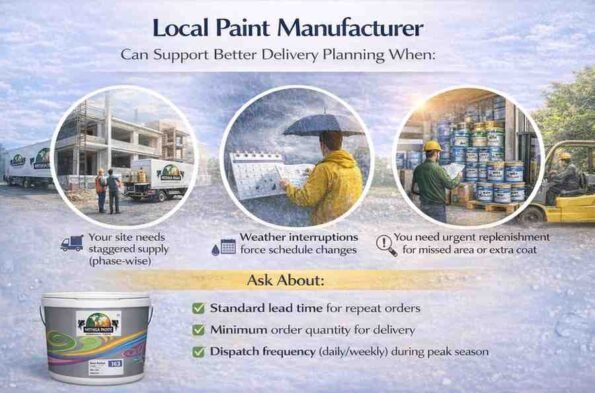

14. Delivery Planning, Stock Availability, and Lead Time

A local paint manufacturer in Salekasa can support better delivery planning when:

- Your site needs staggered supply (phase-wise)

- Weather interruptions force schedule changes

- You need urgent replenishment for missed area or extra coat

Ask about:

- Standard lead time for repeat orders

- Minimum order quantity for delivery

- Dispatch frequency (daily/weekly) during peak season

15. Storage & Handling on Site

Even high-quality paint can fail if stored poorly. Basic rules:

- Store in a shaded, dry area (avoid direct heat)

- Keep lids tightly closed after use

- Use “first in, first out” on batches

- Don’t dilute randomly—follow consistent mixing ratios

- Avoid contamination (dirty rollers, dust, cement mixing nearby)

This reduces wastage and ensures consistent finish across rooms and floors.

16. How to Choose the Right Paint Manufacturer in Salekasa

Here’s a practical evaluation method:

A) Product fit

- Do they offer the paint system you need (interior + exterior + primer)?

- Can they supply repeat orders without quality shift?

B) Consistency proof

- Do they use batch codes?

- Can they provide a sample and repeat the same quality after a few weeks?

C) Support for bulk buyers

- Do they plan delivery schedule and packaging safety?

- Do they provide clear instructions for application and storage?

D) Transparency

- Clear rate structure

- Clear product labeling

- Clear dispatch commitments

17. Common Mistakes Buyers Make

Avoid these frequent errors:

- Choosing only by lowest price

Low cost that leads to extra coats or shade mismatch becomes expensive later. - Skipping primer or surface prep

Causes patchy finish and early peeling complaints. - Mixing different batches without planning

In big areas, mixing batches can create visible variation. - Improper storage at site

Heat and dust contamination can ruin material. - No documentation

Always keep product name, batch code, shade details, and purchase record.

18. Simple Selection Checklist + Comparison Tables

Quick selection checklist (copy-paste)

- Interior + exterior + primer available

- Batch coding and proper labeling present

- Shade repeatability confirmed (sample test)

- Viscosity/flow consistent across buckets

- Strong packaging and sealing

- Clear bulk pricing slabs

- Defined lead time and delivery schedule

- Basic application & storage guidance provided

19. FAQs (Common Questions)

Q1. Why choose a paint manufacturer in Salekasa instead of buying retail paint?

Bulk supply from a paint manufacturer in Salekasa usually offers better rate stability, easier replenishment, and stronger batch consistency for large sites.

Q2. How can I check paint quality quickly before bulk purchase?

Ask for a sample, apply on a test wall section, check coverage, finish uniformity, drying time, and whether shade looks consistent in daylight and indoor light.

Q3. What causes shade variation on walls even with the same paint?

Common reasons include uneven wall absorption (no primer), different batches mixed on one wall, inconsistent dilution, or different application tools.

Q4. For exterior walls, what matters most—price or durability?

Durability matters more. Exterior failures lead to costly repainting and client complaints. A good paint manufacturer in Salekasa should prioritize weather protection and consistent performance.

Q5. How much extra paint should I plan for wastage?

In many projects, planning a small buffer quantity is smart (for touch-ups, corrections, and additional coat requirements). Exact buffer depends on wall condition and labor quality.

Q6. Can local manufacturers handle large projects like apartments or institutions?

Many can, if they have organized production, batching discipline, and delivery planning. Always verify batch consistency and lead time.

20. Conclusion

Choosing the right paint manufacturer in Salekasa is a practical business decision—especially for builders, contractors, and retailers who need consistent finish quality and predictable supply. Focus on batch reliability, shade consistency, packaging standards, and delivery planning—not just the lowest rate.

If you shortlist manufacturers using the checklist above and test samples properly, you’ll reduce repainting risks, improve finishing speed, and deliver better results to your clients.