The construction and real estate sector in and around Tiroda has seen steady growth in recent years. From independent houses to apartment complexes, commercial buildings, and institutional projects, the demand for high-quality and cost-effective paint solutions has increased significantly. As a result, wholesale paint in Tiroda has become the preferred sourcing option for builders, contractors, and property developers.

Buying paint at wholesale level is no longer limited to large projects alone. Even small and mid-sized construction works now rely on wholesale paint suppliers to ensure consistency, budget control, and timely availability. Local wholesale sourcing offers practical advantages that go far beyond pricing.

This guide explains everything you need to know about wholesale paint in Tiroda, including current trends, types of paints, texture usage, quality expectations, market reviews, and why local wholesale sourcing makes sense for modern construction.

Why Wholesale Paint in Tiroda Is in High Demand

Construction timelines are tighter than ever, and material delays can directly impact project completion. Wholesale paint in Tiroda helps builders avoid these challenges by offering steady supply and quick replenishment.

Local wholesale suppliers understand regional demand patterns and stock products accordingly. This ensures builders don’t face last-minute shortages or inconsistent batches during critical project phases.

Key reasons for growing demand include:

- Increased residential and commercial construction

- Rising preference for uniform finishes

- Cost control through bulk procurement

- Reduced dependency on distant suppliers

Advantages of Buying Paint Wholesale in Tiroda

Cost Efficiency and Budget Control

One of the biggest advantages of wholesale paint in Tiroda is cost efficiency. Bulk sourcing reduces per-unit costs and minimizes additional expenses such as long-distance transport and repeated handling.

Builders benefit from:

- Lower logistics expenses

- Stable pricing across project duration

- Predictable material costs

- Improved budgeting accuracy

This makes wholesale paint suitable for both small residential projects and large-scale developments.

Consistent Quality Across Projects

Consistency is critical when painting large areas. Shade variation or finish inconsistency can lead to visible defects and rework.

Wholesale paint in Tiroda allows builders to:

- Source the same batch for the entire project

- Maintain uniform color and finish

- Avoid mismatch issues during repainting or expansion phases

Local wholesalers focus on maintaining batch continuity, which is a major advantage for phased construction projects.

Types of Paints Available Through Wholesale Suppliers

Wholesale paint suppliers in Tiroda typically offer a wide range of products to suit different construction needs.

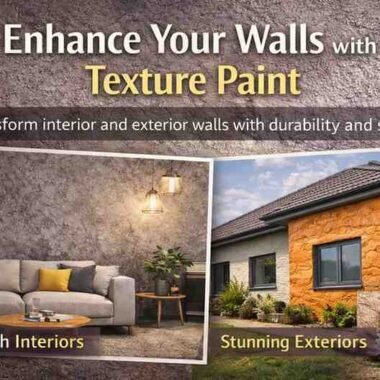

Interior Wall Paints

Interior paints are designed for smooth finish, color richness, and easy maintenance. These are commonly used in:

- Homes and apartments

- Offices and showrooms

- Schools and hospitals

Exterior Wall Paints

Exterior paints provide protection against weather, dust, and surface damage. Wholesale paint in Tiroda includes exterior options suitable for:

- Building elevations

- Boundary and compound walls

- Commercial facades

Primer and Undercoats

Primers ensure proper adhesion and enhance paint life. Wholesale sourcing ensures the same primer type is used throughout the project.

Texture and Decorative Paints

Decorative paints and textures are increasingly sourced along with wholesale paint to meet modern design requirements.

Current Paint and Texture Trends in Tiroda

Construction today is driven by both performance and aesthetics. Builders are adopting new paint and texture trends to enhance project appeal.

Soft Neutral Shades

Neutral colors such as off-white, beige, grey, and pastel tones are widely preferred for both interiors and exteriors.

Matte and Low-Sheen Finishes

Matte finishes are trending due to their premium look and ability to hide surface imperfections.

Textured Feature Walls

Textures are now commonly combined with wholesale paint for:

- Living room feature walls

- Building elevations

- Commercial reception areas

Low-Maintenance Coatings

There is growing demand for paints that retain appearance with minimal upkeep, especially in housing societies and commercial spaces.

Wholesale paint in Tiroda supports these trends by offering bulk availability of trending products.

Role of Wholesale Paint in Residential Construction

Residential projects form a major share of paint consumption. Wholesale paint in Tiroda is widely used for:

- Apartment buildings

- Housing societies

- Interior feature walls

- Exterior elevations

Bulk sourcing helps builders maintain consistency across multiple units while keeping costs under control.

Commercial and Institutional Use of Wholesale Paint

Commercial and institutional buildings require paints that offer durability and easy maintenance.

Wholesale paint in Tiroda is suitable for:

- Offices and IT spaces

- Retail outlets and malls

- Educational institutions

- Hospitals and clinics

- Warehouses and factories

These projects benefit from reliable supply and uniform finish across large surface areas.

Builder and Contractor Reviews: Market Feedback

Builders and contractors who regularly source wholesale paint in Tiroda often report:

- Fewer material-related issues

- Better coordination with suppliers

- Reduced project delays

- Improved finish quality

Local wholesale suppliers are preferred due to faster response and easier communication compared to distant distributors.

Storage and Handling Benefits of Local Wholesale Paint

Paint storage plays an important role in maintaining product quality. Local wholesale sourcing reduces storage duration and risk of spoilage.

Benefits include:

- Better paint workability

- Reduced wastage

- Consistent finish quality

- Lower material loss

This improves overall project efficiency.

Reliability and Supply Chain Stability

Construction delays often occur due to inconsistent material availability. Wholesale paint in Tiroda ensures:

- Faster delivery timelines

- Easy reordering of the same product batch

- Reduced risk of stock unavailability

Reliable supply chains help builders maintain schedules and avoid downtime.

Supporting Local Supply Chains

Choosing wholesale paint in Tiroda supports local businesses and strengthens regional supply chains. Local sourcing reduces dependency on external markets and improves availability during peak construction seasons.

This also helps build long-term supplier relationships, which benefits future projects.

Future Outlook for Wholesale Paint in Tiroda

As construction activity continues to grow, demand for wholesale paint in Tiroda is expected to rise further. Future focus areas include:

- Advanced exterior coatings

- Paints compatible with textured finishes

- Environment-friendly formulations

- Long-life, low-maintenance solutions

Local wholesale suppliers are well-positioned to adapt quickly to these changing requirements.

Conclusion

Wholesale paint in Tiroda has become a strategic choice for builders, contractors, and property developers aiming for cost efficiency, consistency, and reliable supply. From residential housing to commercial and institutional projects, wholesale sourcing ensures smoother execution and better quality control.

With evolving paint trends, increasing use of textures, and growing construction demand, local wholesale paint suppliers will continue to play a vital role in supporting modern construction projects of all scales.