In modern construction, wall finishing is no longer limited to plain paint. Builders and architects now prefer textured finishes because they enhance visual appeal, improve surface durability, and hide minor wall imperfections. A texture manufacturer in Kalmeshwar plays an important role in supplying these advanced wall finishes for residential, commercial, and industrial projects.

Kalmeshwar has emerged as a growing construction hub, increasing the demand for reliable texture manufacturing units that can provide consistent quality, bulk availability, and region-specific formulations. Local texture manufacturers offer practical advantages such as faster delivery, customization, and better pricing, making them a preferred choice over distant suppliers.

This detailed blog explains everything you need to know about a texture manufacturer in Kalmeshwar, including texture types, benefits of local sourcing, quality standards, applications, and selection criteria.

📌 Index

- Introduction to Texture Manufacturer in Kalmeshwar

- Why Wall Textures Are Important in Modern Construction

- Growing Demand for Texture Manufacturer in Kalmeshwar

- Benefits of Choosing a Local Texture Manufacturer

- Types of Wall Textures Manufactured in Kalmeshwar

- Interior Texture Applications and Benefits

- Exterior Texture Solutions for Long-Term Protection

- Raw Materials Used in Texture Manufacturing

- Quality Control and Assurance Process

- Residential Uses of Wall Textures

- Commercial & Industrial Texture Applications

- Bulk Supply Advantages for Builders & Contractors

- Cost Benefits of Local Texture Manufacturing

- Customization Options in Texture Manufacturing

- Delivery, Storage, and Logistics Support

- Climate-Specific Texture Formulations

- How to Choose the Right Texture Manufacturer in Kalmeshwar

- Sustainability and Eco-Friendly Texture Solutions

- Future Scope of Texture Manufacturing in Kalmeshwar

- Conclusion

1. Introduction to Texture Manufacturer in Kalmeshwar

A texture manufacturer in Kalmeshwar produces decorative and protective wall textures used on interior and exterior surfaces. These textures are designed to improve the appearance of walls while also increasing surface strength and durability.

Local manufacturers focus on meeting regional construction needs by offering textures suitable for local climate conditions, building styles, and project budgets. This makes them a dependable source for builders, contractors, and developers.

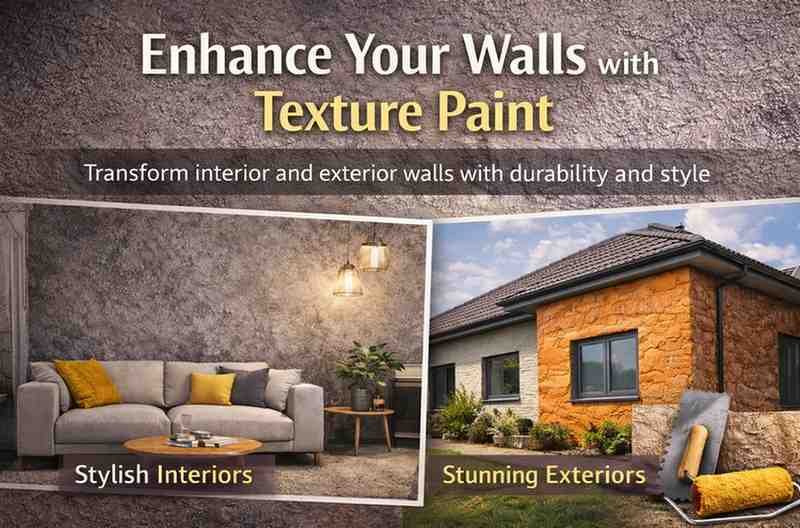

2. Why Wall Textures Are Important in Modern Construction

Wall textures are no longer just decorative elements. They also serve functional purposes in construction projects.

Textured surfaces help hide minor cracks, uneven plaster work, and surface imperfections. At the same time, they enhance the overall look of buildings, giving walls depth and character that plain paint cannot provide.

3. Growing Demand for Texture Manufacturer in Kalmeshwar

The construction activity in and around Kalmeshwar has increased steadily due to residential projects, commercial buildings, and infrastructure development. This growth has created strong demand for texture manufacturer in Kalmeshwar.

Builders prefer local manufacturers because they can supply materials quickly, maintain consistent quality, and support bulk requirements without delays. This local availability reduces dependency on distant suppliers.

4. Benefits of Choosing a Local Texture Manufacturer

Choosing a local texture manufacturer offers multiple practical advantages.

Faster Availability

Textures are readily available, reducing waiting time and preventing project delays.

Better Communication

Direct coordination with manufacturers ensures correct product selection and smoother execution.

Cost Efficiency

Local sourcing reduces transportation and handling costs, making textures more affordable.

5. Types of Wall Textures Manufactured in Kalmeshwar

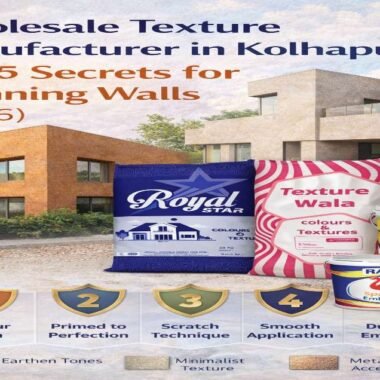

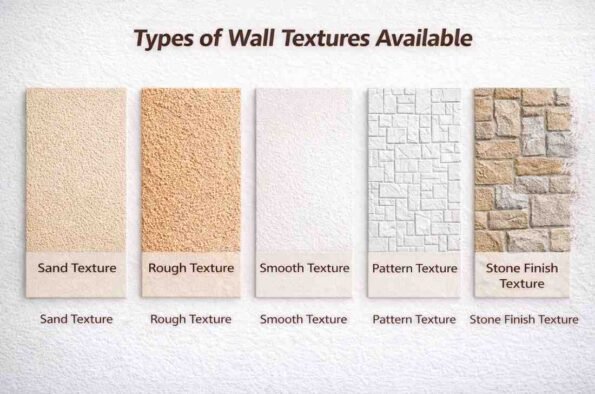

A reliable texture manufacturer in Kalmeshwar produces a wide variety of textures for different applications.

Sand Textures

Sand textures offer a subtle grainy finish that works well for both interior and exterior walls. They provide durability while maintaining a clean appearance.

Rough Finish Textures

Rough textures are ideal for exterior elevations as they provide strong resistance against weather conditions and surface wear.

Smooth Decorative Textures

These textures are used in modern interiors to create elegant feature walls with minimal maintenance.

Designer and Patterned Textures

Patterned textures enhance aesthetics in premium residential and commercial spaces.

6. Interior Texture Applications and Benefits

Interior textures improve both appearance and functionality of indoor spaces.

They add depth to walls, create visual interest, and reduce the visibility of minor wall defects. Interior textures are commonly used in living rooms, bedrooms, offices, and reception areas for a refined finish.

7. Exterior Texture Solutions for Long-Term Protection

Exterior textures protect buildings from environmental damage.

They form a strong protective layer against rain, heat, dust, and UV exposure. Exterior textures also help prevent cracking and peeling, ensuring long-term durability and visual appeal.

8. Raw Materials Used in Texture Manufacturing

The quality of textures depends heavily on raw materials.

Manufacturers use white cement, mineral fillers, polymers, pigments, and performance additives. Proper selection and proportion of these materials ensure strong adhesion, consistent texture, and long-lasting performance.

9. Quality Control and Assurance Process

A professional texture manufacturer in Kalmeshwar follows strict quality control procedures.

Raw materials are inspected before production to ensure standard quality. Batch testing is conducted to maintain uniform texture, grain size, and finish. Finished textures are evaluated for strength, durability, and resistance to environmental conditions.

10. Residential Uses of Wall Textures

Textures are widely used in residential construction.

They enhance interior walls, exterior elevations, balconies, staircases, and compound walls. Textures also improve property value by providing a premium look with long-term durability.

11. Commercial & Industrial Texture Applications

Commercial and industrial projects benefit significantly from textured finishes.

Textures provide uniform appearance across large wall areas, require less frequent maintenance, and withstand heavy usage. Offices, malls, hotels, warehouses, and industrial units commonly use textured coatings.

12. Bulk Supply Advantages for Builders & Contractors

Builders and contractors rely on texture manufacturer in Kalmeshwar for bulk supply needs.

Bulk availability ensures uninterrupted workflow and consistent finish across the entire project. It also helps contractors plan materials efficiently and reduce wastage.

13. Cost Benefits of Local Texture Manufacturing

Local texture manufacturing offers long-term cost advantages.

Lower transportation costs reduce overall expenses. Bulk pricing further minimizes per-unit cost. Durable textures also reduce future repair and repainting costs.

14. Customization Options in Texture Manufacturing

Customization is a major strength of local manufacturers.

Clients can choose specific texture patterns, grain sizes, and shades to match architectural themes. Manufacturers also offer application-specific formulations for interior and exterior use.

15. Delivery and Storage

A reliable texture manufacturer in Kalmeshwar provides strong delivery and logistics support to ensure smooth execution of construction projects. On-time delivery of texture materials helps builders and contractors maintain project schedules, especially in large-scale or time-bound developments.

In addition, safe and moisture-resistant packaging protects texture quality during transportation and storage. Manufacturers also offer clear guidance on proper storage conditions and application methods, ensuring that the texture maintains its consistency, performance, and finish quality until it is applied on site.

16. Climate-Specific Texture Formulations

Textures manufactured locally are specifically formulated to perform well under regional climate conditions. A reliable texture manufacturer in Kalmeshwar develops textures with enhanced heat resistance to withstand high temperatures, along with moisture tolerance to handle monsoon humidity and rainfall.

These climate-specific formulations also provide flexibility, allowing textured surfaces to expand and contract with temperature changes without cracking or peeling. As a result, walls maintain their strength, finish, and appearance for a longer period, ensuring improved long-term performance and reduced maintenance in local environmental conditions.

17. How to Choose the Right Texture Manufacturer in Kalmeshwar

Selecting the right texture manufacturer in Kalmeshwar is essential for ensuring consistent quality and smooth project execution. One of the key factors to consider is the manufacturer’s production capacity, as it determines their ability to handle bulk orders and meet project timelines without supply disruptions.

The product range is equally important, as a reliable manufacturer should offer multiple texture types, finishes, and application-specific formulations to suit different construction requirements. Quality consistency across batches and a strong local market reputation further indicate trustworthiness, ensuring that builders and contractors receive dependable materials, on-time delivery, and long-lasting wall finishes for their projects.

18. Sustainability and Eco-Friendly Texture Solutions

Modern texture manufacturer in Kalmeshwar are increasingly adopting sustainable and eco-friendly manufacturing practices to meet evolving construction standards. The use of low-VOC and water-based texture formulations helps improve indoor air quality, making living and working spaces healthier for occupants while reducing harmful emissions.

Eco-friendly textures also minimize environmental impact during application and throughout the product lifecycle. In addition, efficient production processes such as optimized material usage, reduced waste generation, and energy-conscious manufacturing methods further support sustainable construction practices, making environmentally responsible textures a preferred choice for modern projects.

19. Future Scope of Texture Manufacturing in Kalmeshwar

With continuous growth in residential, commercial, and infrastructure projects, the future of texture manufacturer in Kalmeshwar appears highly promising. Rapid urban development, renovation of old structures, and increased focus on premium wall finishes are driving steady demand for high-quality textures in the region.

The preference for decorative and durable wall coatings is rising as builders and homeowners seek long-lasting solutions that enhance aesthetics while reducing maintenance costs. Locally sourced texture materials are gaining importance due to faster availability, cost efficiency, and better compatibility with regional climate conditions, making local manufacturers a key part of future construction planning.

Additionally, advancements in texture formulations, eco-friendly materials, and customized design options will further expand opportunities for texture manufacturer in Kalmeshwar. As construction standards evolve, demand for innovative, sustainable, and performance-driven textures is expected to grow consistently in the coming years.

20. Conclusion

A texture manufacturer in Kalmeshwar provides reliable, cost-effective, and high-quality wall texture solutions for modern construction needs. Local manufacturing ensures consistency, customization, faster supply, and long-term durability, making it the ideal choice for builders and contractors.